ARAGO PHOTOGRAMMETRY RIG

Designed and Developed by Rigsters in Copenhagen.

Arago is now available for purchase.

SWIPE UP

Fast & Efficient

Key features

5-axis design driven by high-quality stepper motors provides precise and fast motion

Dedicated software Arago Control generates an optimal distribution of image-capture positions for your object. Arago Control significantly decreases the capture time, improves data quality, and optimises the quantity required. Backed by advanced path-finding algorithms that account for your setup, Arago Control enables travelling through positions in a timely yet safe manner

Quick training enables any user to start operating Arago with ease thanks to an intuitive software interface and user-friendly hardware design

Adjustable motor speed control helps with refined motion of more delicate objects

Capture speed calculation

A multitude of variables such as your camera settings, flash recycle, object size and the number of images required to reach the desired quality are taken into account when estimating capture time.

For example:

An object such as a standard-sized shoe – when captured using 300 images/positions at about 50cm distance requires approximately 13-15 minutes depending on your camera settings.

When 700 positions are used to capture the same shoe, requires approximately 20-25 minutes.

Arago Control

Key features

3D interface powered by a digital twin of Arago visualises the real-time operation with high fidelity

Camera control provides tethered and camera-agnostic options for adjusting your camera settings on the go. Camera calibration features assure the exact placement and properties of virtual cameras

Object Prescan quickly reads the shape, curvature and position in space of your object. Establishing a proxy 3D model facilitates optimal camera position generation

Position generation tools enable you to easily produce the optimal capture set with adaptive amount and coverage of positions. A flexible generation algorithm calculates camera positions by accounting for the shape of the object, surroundings, and user-defined settings

Video showcase

Large & Small objects

Key features

Flexible object volume varying between 5 – 180 cm depending on the configuration of the turntable module and camera field of view

360-degree Turntable with a side-to-side motion and a payload of 80 KG. It comes with 30 – 60 cm extension modules for additional object elevation and flexible mounting options

Detachable turntable module enables capture of larger objects and ensures absolute safety

Camera tilting component provides additional reach around the scanning area and can accommodate up to 10kg of equipment

Portable Design

Key features

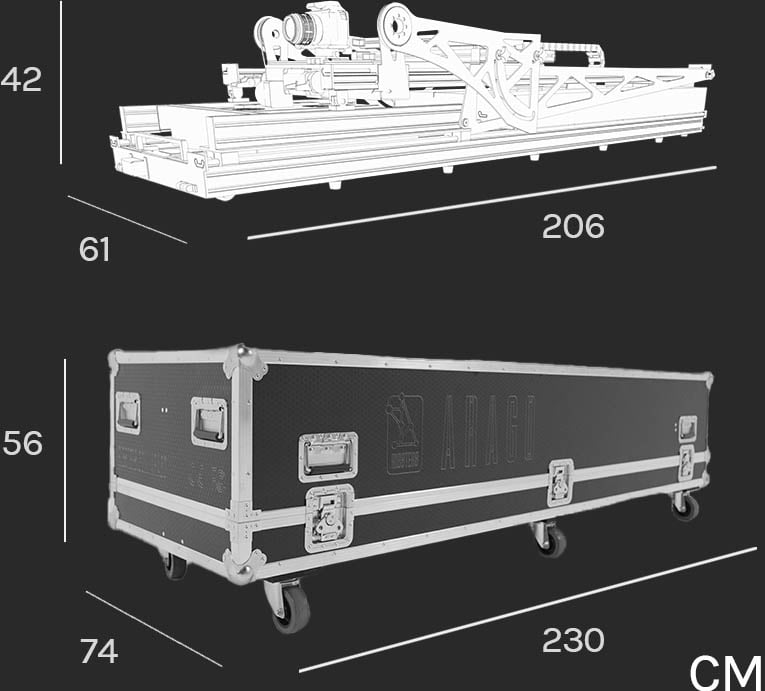

2-minute assembly (or disassembly) time thanks to the intuitive foldable design

Durable and robust construction of Arago ensures longevity and stable 24/7 operation

Shockproof flight case is custom-made to suit the Arago unit. It includes a storage compartment to accommodate all the accessories

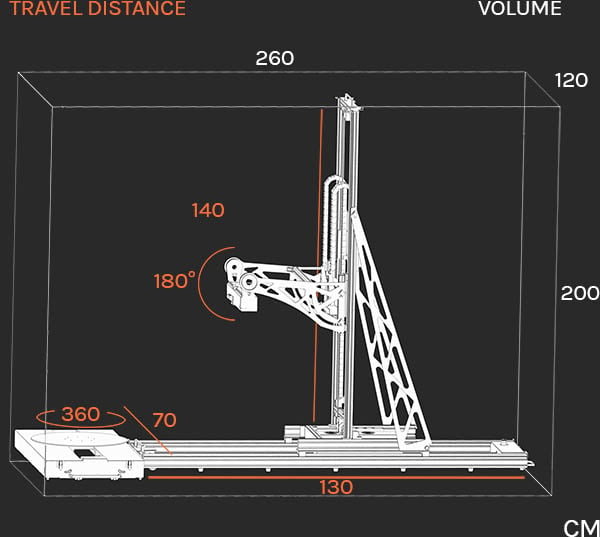

Dimensions

Supported Gear

Key features

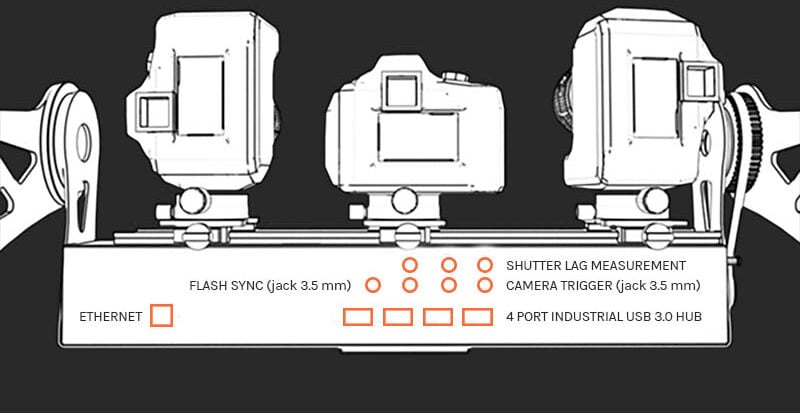

Camera tilt module provides extended I/O options for stable communication with your gear. Side-to-side sliding mounting plates can accommodate the majority of standard photography equipment

Support for up to 3 digital cameras along with Auto Shutter sync across cameras with up to 1/200s speeds

On-board power extender allows you to have direct power to your cameras, lights, and other equipment

Arago I/O

ARAGO

Developed for mass-digitization of objects, Arago automates the tedious process of capturing images for photogrammetry.Arago Control software generates optimal camera positions for the object of your choice.

Arago has been successfully integrated in the production pipelines of many 3D Creators, including:

Book a Demo

Discover how Arago can help your digitization needs and ask us all your questions in a free online video call Or reach out directly to [email protected]

Subscribe to the newsletter

Arago news and updates in your inbox.